Cross Docking

Now, here is an approach that's sure to interest you if you have a high volume of items that needing dispatching, but want your warehouse to be as small as possible.

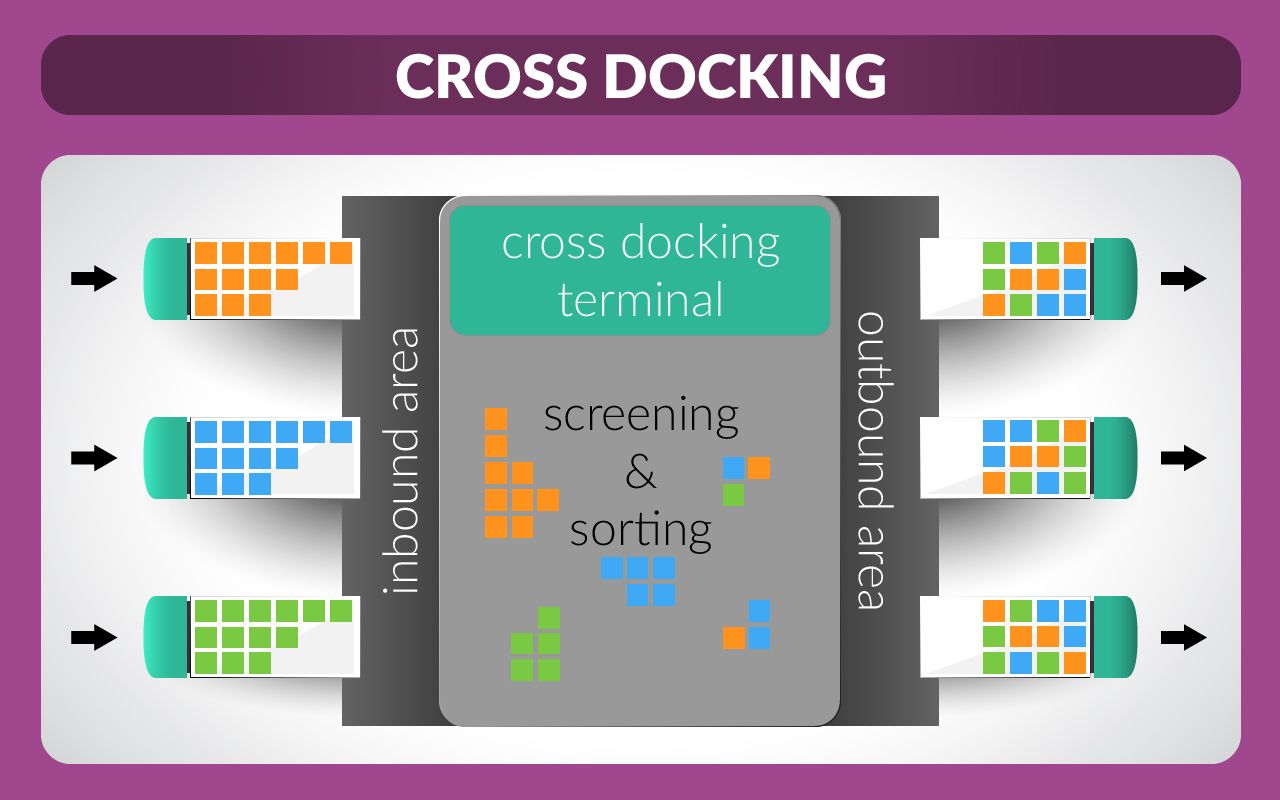

It's called cross Docking and is a bit more complicated than drop-shipping. You need to have a warehouse for cross Docking, but it's not really used as a storage space. Instead, items that come from different suppliers are placed in a docking station. In the docking area, they are sorted and put together in a single shipment package for each destination. Then, the shipments are loaded onto trucks and vans and shipped to their final destination.

The whole process should normally take no more than a day, so that your stock is actually always at the point of sale and your warehouse serves as a sorting area rather than storage space. Cross Docking seamlessly integrates within our Warehouse Management System as a standard function.

Cross Docking has been around for generations. Yet, now more than ever, retailers are moving goods and products from the receiving dock directly to the shipping dock as a more efficient way to bridge “the final mile.”

Consider these five reasons when exploring whether your retail operation can benefit from a Cross Docking solution:

- Keep up with the clicks. Consumer demand and competition from eCommerce sites such as Amazon, Google and other Internet-based retailers has pushed traditional brick-and-mortar retailers to up their game. For many, same day / next day fulfillment for both in-store and online purchases is the new normal. This also requires retailers keep store shelves stocked, while also keeping costs in check. Pushing product closer to the storefront faster has become the competitive mandate.

- Match consumer shopping habits. As consumers shop nights and especially weekends, retailers need faster replenishment, without giving up valuable retail space. Just-in-time restocking ensures product is on hand when consumers reach for it.

- Tight in-store inventory. Store-rooms don’t sell goods. Showrooms do. For years, retailers have tried to push more inventory out front. Cross Docking allows retailers to reduce the size of storerooms – and transform that floor space into retail selling space.

- Improve inventory management and damage control. More frequent or just-in-time replenishment allows retailers to break the case to allocate goods piecemeal or at significantly lower quantities to store locations, as opposed to shipping and storing entire boxes of merchandise. This also can reduce the likelihood of damage to stored inventory

- Accommodate flexible delivery schedules. Some stores can’t take deliveries on certain days. Others aren’t staffed to handle inbound loads. Smaller cross-docked loads can often be scheduled to match individual store locations’ logistical or staffing realities, with appointment windows as tight as one hour.

Traditional brick-and-mortar retailers that have not explored cross docking in the past should discuss the benefits of Cross Docking with Nebraska Warehouse, a 3PL provider with the right facilities, processes, and personnel.