Here’s a question to consider for you operations-minded brains: should you cross dock?

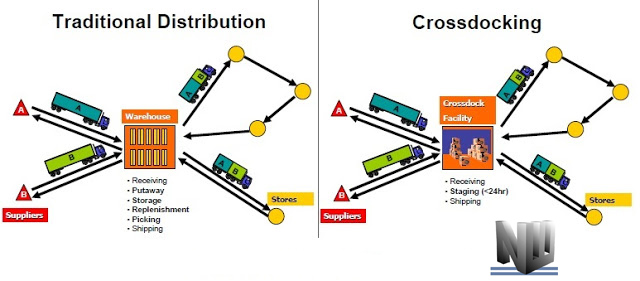

For those less fulfillment-inclined, cross docking refers to moving product from a manufacturer to a fulfillment warehouse, who then turns and delivers it directly to the customer with little or no material handling in between.

Why would you do that? Sometimes, it makes more sense for a retailer to cross dock an item than it does to hold it in inventory. For example: you carry a very unique piece of jewelry that appeals to a small portion of your target market. It’s so unique that it’s difficult to find with other retailers, but it doesn’t sell more than 100 a year. You want to continue selling the product, fully packaged in your pretty pink box with your logo on the side that your customers know you for, but you don’t want the jewelry sitting in your warehouse taking up space (and costing you money!) when you have other items that turn over more quickly.

Answer: cross dock.

Is it right for you? It all depends on your ecommerce business goals. Here’s a breakdown of the benefits:

BENEFITS

- Reduced labor costs – Cross docking eliminates the “pick” in pick, pack, and ship, saving valuable time in the order lifecycle. Also, since the product is coming directly from the manufacturer or wholesaler ready to ship, there’s no inventory replenishment involved inside the warehouse.

- Reduced warehouse footprint – For retailers with a limited warehouse footprint (or who would rather free up space for higher-selling or higher-value SKUs), cross docking makes sense. Since that item isn’t in stock, it’s not sitting on the warehouse floor taking up valuable space – and possibly costing you money.

- No inventory ownership – When you cross dock, the product comes in, gets scanned into your OMS, and then heads back out. There’s no need to inventory the item, set up reorder instructions, pay vendors for large orders, or be tracking the SKU for shrinkage or damage. The inventory is owned by the sending company only!

- Easier for bulk orders – If you’ll be selling items in lots, it’s much easier to have them packaged, labeled, and ready to ship at the dock than it is to pick and assemble a package of those items before shipment.

“But why not just drop ship the product instead?” you might ask.

Well, in some cases that does actually make more sense, but if a retailer wants to control the customer’s overall brand experience (i.e. custom packaging, labeling, shipping an order complete versus split-shipping an order, etc.) then cross docking becomes a more attractive option.

When done correctly, cross docking can give retailers a wider product mix without the headache of more inventory management, while still giving them the opportunity to have control over the customer experience.